The post GND Diamond Series appeared first on Gains Diamond Powder For You.

]]>| Size / Grade | 25/30 | 30/35 | 35/40 | 40/50 | 50/60 | 60/70 |

|---|---|---|---|---|---|---|

| GND30 | ★ | ★ | ★ | ★ | ★ | ★ |

| GND40 | ★ | ★ | ★ | ★ | ★ | ★ |

| GND50 | ★ | ★ | ★ | ★ | ★ | ★ |

| GND60 | ★ | ★ | ★ | ★ | ★ | ★ |

| GND70 | ★ | ★ | ★ | ★ | ★ | ★ |

| GND80 | ★ | ★ | ★ | ★ | ★ | ★ |

| GND90 | ★ | ★ | ★ | ★ | ★ | ★ |

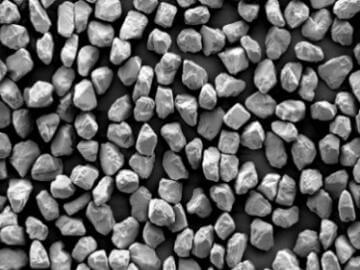

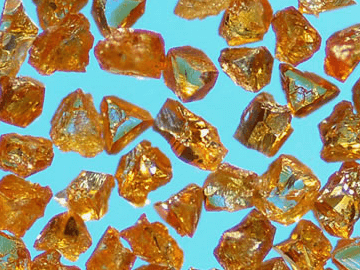

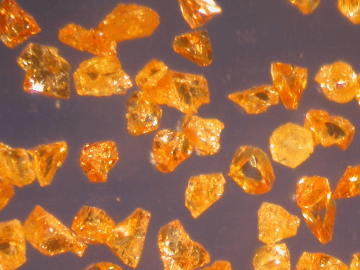

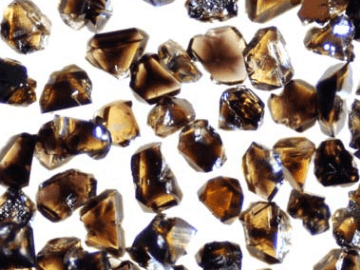

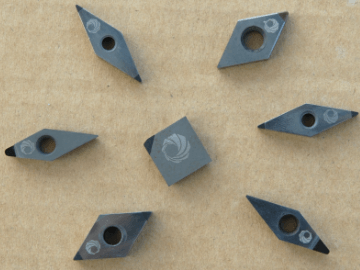

Superhard material offers a complete range of coarse synthetic diamond powder,this series is mainly for sawing and drilling applications. The highest level of product quality and consistency let the premium diamond widely used in the mining, oil and gas , stone processing, renovation and construction industries.

Located in China, if you purchase from us, we offer many additional convenient services, all of which cannot be easily provided by other superhard material suppliers.

The post GND Diamond Series appeared first on Gains Diamond Powder For You.

]]>The post Micron Powder appeared first on Gains Diamond Powder For You.

]]>| Size / Grade | GNM-A | GNM-B | GNM-C |

|---|---|---|---|

| 0-0.25 | ★ | ★ | |

| 0.5 | ★ | ★ | ★ |

| 0-1 | ★ | ★ | ★ |

| 0-2 | ★ | ★ | ★ |

| 1-3 | ★ | ★ | ★ |

| 4-6 | ★ | ★ | ★ |

| 4-8 | ★ | ★ | ★ |

| 5-10 | ★ | ★ | ★ |

| 6-12 | ★ | ★ | ★ |

| 7-14 | ★ | ★ | ★ |

| 8-16 | ★ | ★ | ★ |

| 10-20 | ★ | ★ | ★ |

| 12-22 | ★ | ★ | ★ |

| 15-25 | ★ | ★ | ★ |

| 20-30 | ★ | ★ | ★ |

| 22-36 | ★ | ★ | ★ |

| 30-40 | ★ | ★ | ★ |

| 40-60 | ★ | ★ | ★ |

| 36-54 | ★ | ★ | ★ |

| 54-80 | ★ | ★ | ★ |

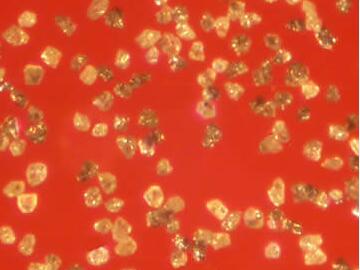

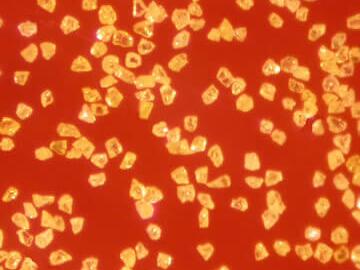

GNM-A Characteristics:

Adopting semiautomatic technology, highly concentrated size distribution, small coefficient of variation; Special treatment makes grain surface absorbing few impurities; Favorable hydrophilic performance thorough surface modification.

Recommended Applications:

High standards required lapping,polishing,etc;High-grade diamond tools manufacturing;High-grade diamond sprays,suspension liquid manufacturing.

GNM-B Characteristics:

Narrow size distribution,small coefficient of variation;Regular shape,particle similar with a shape of ball;Low impurities,surface pureness,and fastness with bond.

Recommended Applications:

Gem stone, glass, ceramic and other related products processing; Diamond grinding wheel, PCD and other super-abrasive tools manufacturing.

GNM-C Characteristics:

Excellent diamond with high strength as well as low impurities as raw material; High strength, higher polishing capacities; Low impurities(intrinsic and extrinsic), good thermal stability.

Recommended Applications:

Lapping or polishing work pieces with metal, ceramic bond.

The post Micron Powder appeared first on Gains Diamond Powder For You.

]]>The post Cubic Boron Nitride appeared first on Gains Diamond Powder For You.

]]>| Size / Grade | GBN-A10 | GBN-A20 | GBN-B10 | GBN-B20 | GBN-C10 | GBN-C20 | GBN-G10 |

|---|---|---|---|---|---|---|---|

| 60/70 | ★ | ★ | ★ | ★ | ★ | ★ | ★ |

| 70/80 | ★ | ★ | ★ | ★ | ★ | ★ | ★ |

| 80/100 | ★ | ★ | ★ | ★ | ★ | ★ | ★ |

| 100/120 | ★ | ★ | ★ | ★ | ★ | ★ | ★ |

| 120/140 | ★ | ★ | ★ | ★ | ★ | ★ | ★ |

| 140/170 | ★ | ★ | ★ | ★ | ★ | ★ | ★ |

| 170/200 | ★ | ★ | ★ | ★ | ★ | ★ | ★ |

| 200/230 | ★ | ★ | ★ | ★ | ★ | ★ | ★ |

| 230/270 | ★ | ★ | ★ | ★ | ★ | ★ | ★ |

| 270/325 | ★ | ★ | ★ | ★ | ★ | ★ | ★ |

| 325/400 | ★ | ★ | ★ | ★ | ★ | ★ | ★ |

| 400/500 | ★ | ★ | ★ | ★ | ★ | ★ | ★ |

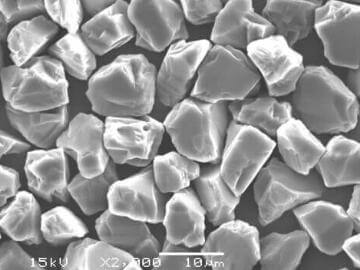

Description:

Cubic Boron Nitrite (CBN) is a durable industrial abrasive that provides superior life, geometry and finish. For application involving the processing of iron alloys, CBN is a better choice. CBN powder is used primarrily in grinding wheels and honing tools to machine hard ferrous workpiece materials. These tools are used extensively in the automotive and aerospace industries to produce high precision components. CBN powder can also be used in PCBN manufacturing.

Main Features:

monocrystalline atructure, angular shaps in each grain, well suited for applications with ferrous materials

Classification:

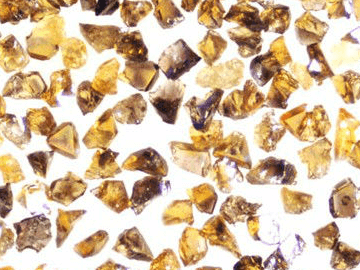

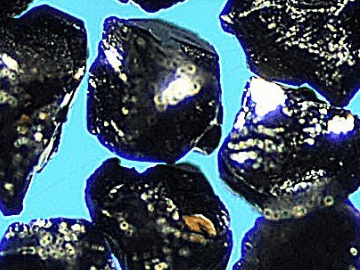

Two types of CBN powders are classified according to different raw materials: Black CBN powder and amber CBN powder.

Usage: babck CBN powder is used in polycrystalline compound as well as lapping and grinding of ferrous metals.

Ambl CBN powder has better crystallinity, purity,toughness impact, stability in comparision to black CBN powder. It is used in the sintering of polycrystalline diamond compounds as well as lapping ,grinding and super finish.

Applied in metal, ceramic bond tools, sharpener, grinding wheels, process of black metal and alloy

The post Cubic Boron Nitride appeared first on Gains Diamond Powder For You.

]]>The post Gem Diamonds appeared first on Gains Diamond Powder For You.

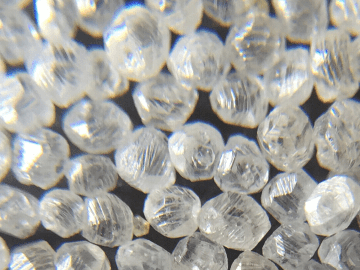

]]>Synthetic gem diamonds, also known as Lab-grown diamonds, man-made diamonds, cultured diamonds, synthetic diamonds or pure grown diamonds, are composed of the same chemical crystal as natural diamonds and exhibit the same fire, scintillation, and sparkle. Gem diamonds are produced using a technological innovation that yields diamonds of exceptionally high quality and purity.

Synthetic gem diamonds do not require any diamond mining, making them a perfect choice for those seeking to minimize the environmental impact of a jewelry purchase. So, the cultured diamonds are conflict-free, eco-friendly and sustainable-creating economic growth opportunity from jewellery to hi-technology industry and makes its future promising.

The post Gem Diamonds appeared first on Gains Diamond Powder For You.

]]>The post PDC for Oil & Gas appeared first on Gains Diamond Powder For You.

]]>| Code # | Diameter (mm) | Height (mm) | Diamond Layer (mm) | Diamond Chamfer X45° | WC Chamfer X45° | Wear Ratio (X10000) | Impact Resistance (J) |

|---|---|---|---|---|---|---|---|

| 1308SY | 13.44 | 8.0 | 1.8~2.0 | 0.5 | 0.5 | >40 | >1600 |

| 1313SY | 13.44 | 13.2 | 1.8~2.0 | 0.5 | 0.5 | >40 | >1600 |

| 1608SY | 16.05 | 8.0 | 1.8~2.0 | 0.5 | 0.5 | >40 | >1800 |

| 1613SY | 16.05 | 13.2 | 1.8~2.0 | 0.5 | 0.5 | >40 | >1800 |

| 1908SY | 19.05 | 8.0 | 1.8~2.0 | 0.5 | 0.5 | >40 | >2000 |

| 1913SY | 19.05 | 13.2 | 1.8~2.0 | 0.5 | 0.5 | >40 | >2000 |

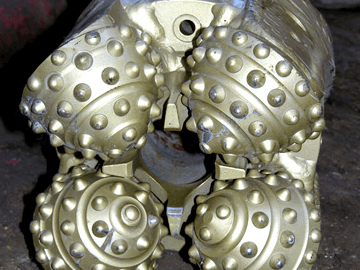

Main Feature:

- Excellent ware ability and impact resistance

- Long useful life, high efficiency, and good cost performance

- The useful life of the PDC bit is 4~5 times than the diamond bit, 10 times then the tungsten carbide bit

Application:

SY series PDC is suitable for soft and medium aggregate rock formations.

The post PDC for Oil & Gas appeared first on Gains Diamond Powder For You.

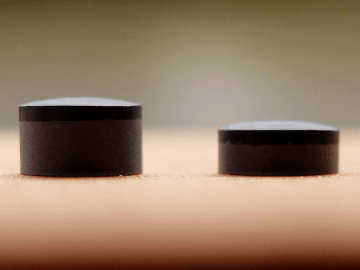

]]>The post PDC for Mining appeared first on Gains Diamond Powder For You.

]]>| Code # | Diameter (mm) | Diamond Layer (mm) | Height (mm) | Wear Ratio (X10000) | Impact Resistance (J) |

|---|---|---|---|---|---|

| 1604 | 16.00 | 1.0~2.5 | 4.5 | >50 | >400 |

| 1608 | 16.00 | 1.0~2.5 | 8.0 | >50 | >400 |

| 1613 | 16.00 | 1.0~2.5 | 13.2 | >50 | >400 |

| 1904 | 19.05 | 1.0~2.5 | 4.5 | >50 | >400 |

| 1908 | 19.05 | 1.0~2.5 | 8.0 | >50 | >400 |

| 1913 | 19.05 | 1.0~2.5 | 13.2 | >50 | >400 |

| 2504 | 25.00 | 1.0~2.5 | 4.5 | >50 | >400 |

| 3204 | 34.00 | 1.0~2.5 | 6.0 | >50 | >400 |

16-34 series are widely used in the big bits of geological prospecting and mining exploring. The character of this series is high hardness, high abrasive resistance, good thermal conductivity and high impact resistance. This mining PDC can improve the drill life and efficiency of drill bits even under the rugged condition.

Application:

- Suitable for F8-F10 Rock formations;

- With high hardness, high abrasive resistance, good thermal conductivity and high impact resistance;

- Mainly used in the big bits of geological prospecting and mining exploring.

The post PDC for Mining appeared first on Gains Diamond Powder For You.

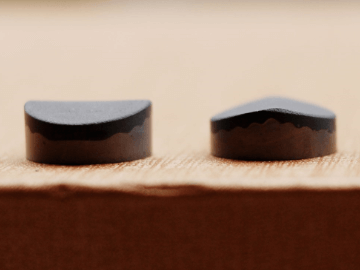

]]>The post PDC for Geological Prospecting appeared first on Gains Diamond Powder For You.

]]>| Code # | Diameter (mm) | Diamond Layer (mm) | Height (mm) | Wear Ratio (X10000) | Impact Resistance (J) |

|---|---|---|---|---|---|

| 1004Z | 10.00 | 1.0~1.1 | 4.5 | >52 | >400 |

| 1004ZS | 10.00 | 1.5~2.5 | 4.5 | >52 | >400 |

| 1304Z | 13.44 | 1.0~1.1 | 4.5 | >52 | >400 |

| 1308Z | 13.44 | 1.0~1.1 | 8.0 | >52 | >480 |

| 1308Z | 13.33 | 1.7~2.2 | 4.5 | >55 | >480 |

| 1304ZS | 13.44 | 1.5~2.5 | 4.5 | >55 | >480 |

| 1308ZS | 13.44 | 1.5~2.5 | 8.0 | >55 | >480 |

| 1303 | 13.44 | 1.0~1.3 | 3.5 | >55 | >480 |

| 1313 | 13.44 | 1.5~3.0 | 13.2 | >55 | >480 |

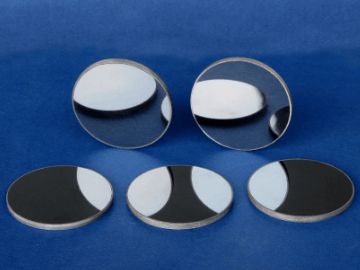

Z series PDC are widely used in geological prospecting and mining exploration, etc. With high hardness, high abrasive resistance,

good thermal conductivity, high impact and firm and steady interface, this can effectively prevent the shedding of diamond layer

and bit balling. Drilling efficiency and drilling dimension can be greatly improved.

Application:

- Suitable for F8-F10 Rock formations;

- With high hardness, high abrasive resistance, good thermal conductivity and high impact resistance;

- It is the ideal material for non-core and core drill bits of geology and mining.

The post PDC for Geological Prospecting appeared first on Gains Diamond Powder For You.

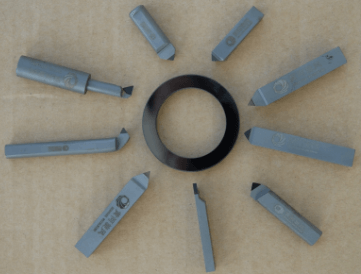

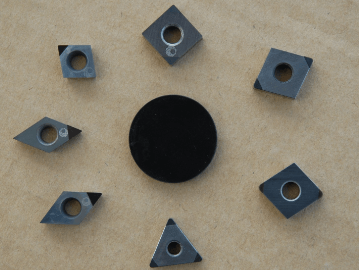

]]>The post PCD (Polycrystalline Diamond) appeared first on Gains Diamond Powder For You.

]]>| Code # | Diameter (mm) | Diamond Layer (mm) | Height (mm) | Diamond Size (µm) |

|---|---|---|---|---|

| GNPD032-A | 48.0 | 0.5±0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 30+2 |

| GNPD032-B | 48.0 | 0.5±0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 30+2 |

| GNPD025-A | 48.0 | 0.5±0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 25 |

| GNPD025-B | 48.0 | 0.5±0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 25 |

| GNPD012-A | 48.0 | 0.5±0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 10+2 |

| GNPD010-A | 48.0 | 0.5±0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 10 |

| GNPD010-B | 48.0 | 0.5±0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 10 |

| GNPD010-C | 48.0 | 0.5±0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 10 |

| GNPD005-A | 48.0 | 0.5±0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 5 |

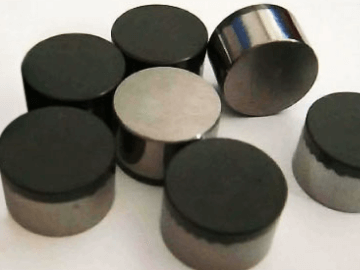

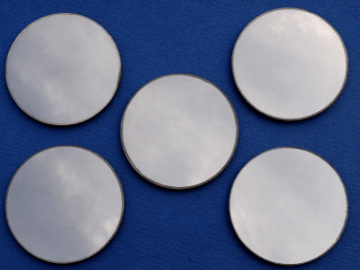

PCD is widely used for machining non-ferrous metals and alloys, such as aluminum, copper, aluminum/gray iron composites,

as well as nonmetallic materials such as wood, chipboard, ceramics, plastic, rubber etc, where high abrasion resistance and

good surface finish are required. Gains offered a wide range of PCD for different application, and can cut the segments

size as the customer request.

The post PCD (Polycrystalline Diamond) appeared first on Gains Diamond Powder For You.

]]>The post Pro Asphalt Blades appeared first on Gains Diamond Powder For You.

]]>| Outer Diameter (D) | Outer Diameter (D) | Arbor Size(H)mm | Segment Dimension (mm) | Segment Dimension (mm) | Core Thickness (mm) | Core Thickness (mm) | Welding Method | Welding Method |

|---|---|---|---|---|---|---|---|---|

| Inches | Metric | Thickness (T) | Height (X) | K | U | Braze welded | Laser welded | |

| 12 | 300 | 25.4/30.5/50 | 3.0 | 7/10 | 21 | 18 | ★ | ★ |

| 14 | 350 | 25.4/30.5/50 | 3.2/3.4 | 7/10 | 24 | 21 | ★ | ★ |

| 16 | 400 | 25.4/30.5/50 | 3.4/3.6 | 7/10 | 28 | 24 | ★ | ★ |

| 18 | 450 | 25.4/30.5/50 | 3.6/3.8 | 7/10 | 32 | 28 | ★ | ★ |

| 20 | 500 | 25.4/30.5/50 | 4.0 | 7/10 | 36 | 30 | ★ | ★ |

| 24 | 600 | 25.4/30.5/50 | 4.8 | 7/10 | 42 | 36 | ★ | |

| 28 | 700 | 25.4/50/80 | 5.0 | 7/10 | 46 | 42 | ★ | |

| 32 | 800 | 50/60/80/100 | 6.0 | 7/10 | 56 | 46 | ★ | |

| 36 | 900 | 80/100 | 6.5 | 7/10 | 64 | 60 | ★ | |

| 40 | 1000 | 80/100 | 7.0 | 10 | 70 | 70 | ★ | |

| 48 | 1200 | 80/100 | 7.5 | 10/12 | 80 | 80 | ★ |

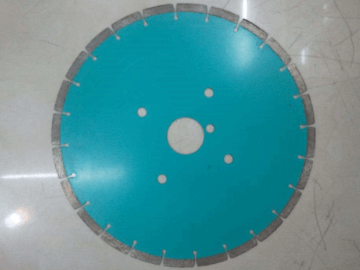

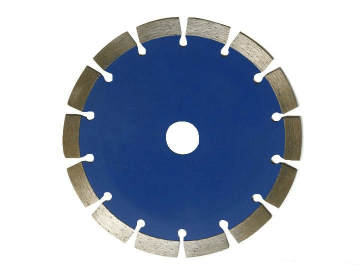

Pro Asphalt Blade is designed for cutting highly abrasive materials including asphalt, asphalt over concrete and green concrete. These blades are to be used on saws of 35hp or less. Redius protected segments for undercutting are standard. Several bonds available to insure performance in each application.

The post Pro Asphalt Blades appeared first on Gains Diamond Powder For You.

]]>The post Wall Saw Blade appeared first on Gains Diamond Powder For You.

]]>- Wall Saw Blade Segment Depth 12mm (.475″) Laser Welded

| Stright Segment | Spilt Segment | Specification |

|---|---|---|

| SPW 18A | SPWS 18A | 18″ x .187 x .480″/12mm |

| SPW 18B | SPWS 18B | 18″ x .250 x .480″/12mm |

| SPW 20A | SPWS 20A | 20″ x .187 x .480″/12mm |

| SPW 20B | SPWS 20B | 20″ x .250 x .480″/12mm |

| SPW 24A | SPWS 24A | 24″ x .187 x .480″/12mm |

| SPW 24B | SPWS 24B | 24″ x .250 x .480″/12mm |

| SPW 26A | SPWS 26A | 26″ x .187 x .480″/12mm |

| SPW 26B | SPWS 26B | 26″ x .250 x .480″/12mm |

| SPW 30A | SPWS 30A | 30″ x .187 x .480″/12mm |

| SPW 30B | SPWS 30B | 30″ x .250 x .480″/12mm |

| SPW 32A | SPWS 32A | 32″ x .187 x .480″/12mm |

| SPW 32B | SPWS 32B | 32″ x .250 x .480″/12mm |

| SPW 36A | SPWS 36A | 36″ x .187 x .480″/12mm |

| SPW 36B | SPWS 36B | 36″ x .250 x .480″/12mm |

| SPW 42A | SPWS 42A | 42″ x .187 x .480″/12mm |

| SPW 42B | SPWS 42B | 42″ x .250 x .480″/12mm |

| SPW 48A | SPWS 48A | 48″ x .187 x .480″/12mm |

| SPW 48B | SPWS 48B | 48″ x .250 x .480″/12mm |

| SPW 54 | SPWS 54 | 54″ x .250 x .480″/12mm |

| SPW 60 | SPWS 60 | 60″ x .250 x .480″/12mm |

We have designed two segment patterns for operating on hydraulic, electric or pneumatic wall saws. These blades employ 12mm (.475″) segments that are laser welded to the core. These blades are available in sizes 18″ through 60″ with segment width of .187(A) or .250(B). These blades will provide fast cutting and long life on reinforced concrete with varied aggregates. Wall saw blades have flush cut holes on all sizes. Please specify if an arbor hole larger that 1″ is required.

Bond Selection Guideline

| Bond Code | Aggregate Listings |

|---|---|

| M01 | Hard Aggregate, Fast Cutting on Hydraulic, Pneumatic and Electric Saws |

| M02 | Medium Aggregate, Fast on Hydraulic, Pneumatic and Electric Saws |

| M03 | Softer, Abrasive Aggregate, Block and other Masonry Material, Longer life on Hydraulic, Electric and Pneumatic Saws |

- Hydraulic Handsaw Blades Segment Depth 12mm (.480″) Laser Welded

| Stright Segment | Spilt Segment | Specification |

|---|---|---|

| SPH 14 | SPHS 14 | 14″ x .125 x .480″/12mm |

| SPH 16A | SPHS 16A | 16″ x .125 x .480″/12mm |

| SPH 16B | SPHS 16B | 16″ x .155 x .480″/12mm |

| SPH 20A | SPHS 20A | 20″ x .125 x .480″/12mm |

| SPH 20B | SPHS 20B | 20″ x .140 x .480″/12mm |

| SPH 20C | SPHS 20C | 20″ x .155 x .480″/12mm |

| SPH 24A | SPHS 24A | 24″ x .125 x .480″/12mm |

| SPH 24B | SPHS 24B | 24″ x .140 x .480″/12mm |

| SPH 24C | SPHS 24C | 24″ x .155x .480″/12mm |

| SPH 26 | SPHS 26 | 26″ x .155 x .480″/12mm |

| SPH 30 | SPH 30 | 30″ x .155 x .480″/12mm |

Gains offers a variety hydraulic hand saw blades. These blades are engineered for fast cutting on all makes of hand saws on the market. These blades come with flush cut hole pattern and available in sizes 14″ through 30″. These blades come in two bonds for fast cutting in hard aggregates and longer life in medium aggregates and two segment types, straight segment and split segment. Laser Welded with 12mm (.475) segment height.

Bond Selection Guideline

| Bond Code | Aggregate Listings |

|---|---|

| M01 | Hard Aggregate, Fast Cutting on Hydraulic, Pneumatic and Electric Saws |

| M02 | Medium Aggregate, Fast on Hydraulic, Pneumatic and Electric Saws |

| M03 | Softer, Abrasive Aggregate, block and other masonry material, Longer life on Hydraulic, Electric and Pneumatic Saws |

The post Wall Saw Blade appeared first on Gains Diamond Powder For You.

]]>